China has taken a major leap toward the future of smart manufacturing with the unveiling of a new generation of AI-powered humanoid robots aimed at transforming its industrial sector. The initiative is part of a national strategy to boost productivity, reduce dependency on human labor in hazardous environments, and secure China’s position as a global leader in advanced manufacturing technologies.

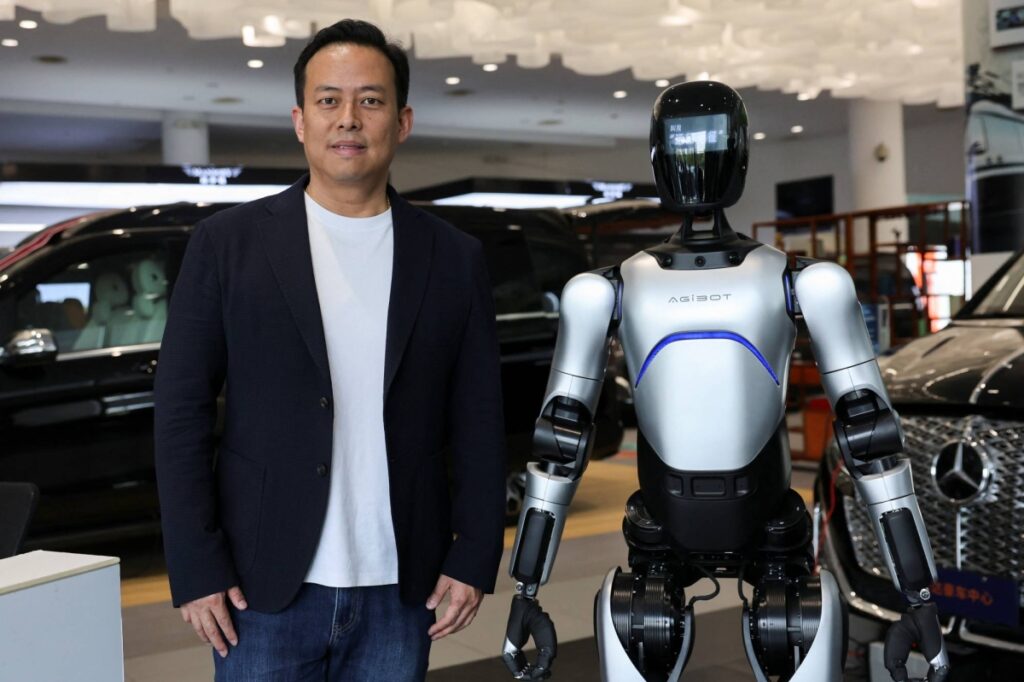

Developed by a consortium of state-backed tech firms, robotics startups, and academic institutions, these humanoid robots are equipped with advanced machine vision, real-time decision-making capabilities, and dexterous mobility systems. Unlike traditional industrial robots that perform repetitive tasks in isolation, these AI-integrated humanoids are designed to work alongside human workers on complex tasks, adapt to changing environments, and even learn from human behavior.

According to China’s Ministry of Industry and Information Technology (MIIT), the robots are currently being piloted in key industrial hubs including Shenzhen, Suzhou, and Chengdu, across sectors such as electronics assembly, automotive production, and heavy machinery maintenance.

The rollout signals a shift from traditional automation to what industry leaders are calling “cognitive robotics” systems that can understand, reason, and make decisions in real time. China’s humanoid robots feature natural language processing for verbal commands, AI-driven sensor fusion for better spatial awareness, and cloud-connected neural networks to share learnings across factories nationwide.

“The future of manufacturing will not just be about machines working faster, but about intelligent machines working smarter,” said Li Zhang, CTO at Mech-Mind Robotics, one of the key developers involved. “Our AI robots are trained not just to replicate actions, but to respond dynamically to problems, improvise when needed, and collaborate intuitively with human teammates.”

China’s push toward humanoid robotics is driven by a combination of long-term demographic trends, including an aging workforce and rising labor costs, and its strategic ambition to lead the global AI race. As global supply chains continue to evolve, the integration of smart robotics into manufacturing is seen as a critical step toward building more resilient, automated production lines.

Analysts suggest that this technology could offset some of the workforce challenges China faces in maintaining its manufacturing dominance, while helping Chinese firms become more agile and cost-effective in a competitive global landscape.

This development places China in direct competition with other major players in the humanoid robotics space, including Tesla’s Optimus robot, Boston Dynamics’ AI-integrated Atlas, and Japan’s industrial robotics leaders like FANUC and Kawasaki.

However, China’s advantage may lie in its ability to rapidly deploy AI infrastructure at scale, backed by state funding, vast datasets, and an aggressive innovation agenda.

“China’s model of tightly integrating AI, robotics, and industrial policy creates a powerful formula for disruptive change,” noted Dr. Nina Cheng, a robotics researcher at Tsinghua University. “This is not just a technological upgrade, it’s a wholesale rethinking of how factories will operate in the future.”

China’s AI-powered humanoid robots are expected to be rolled out more broadly in late 2025, with further enhancements including autonomous maintenance abilities, emotional recognition for safer human-robot interaction, and integration with smart factory systems.

While challenges remain around cost, ethical use, and workforce displacement, the launch marks a significant milestone in China’s vision to become the world’s smart manufacturing superpower.

As one industry observer put it: “The robots are no longer coming. In China, they’ve arrived and they’re ready to work.”